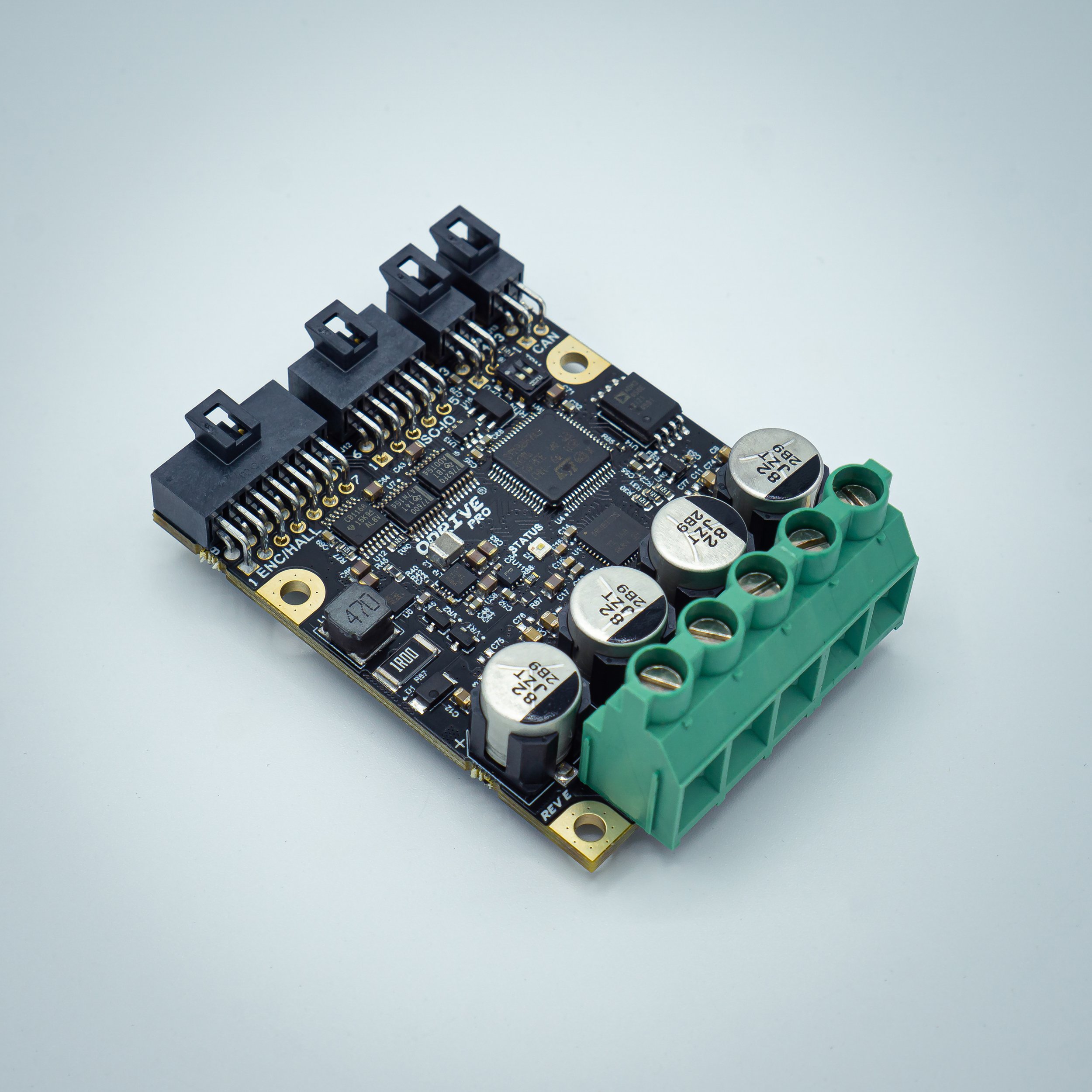

ODrive Pro

ODrive Pro

Includes a thermal pad

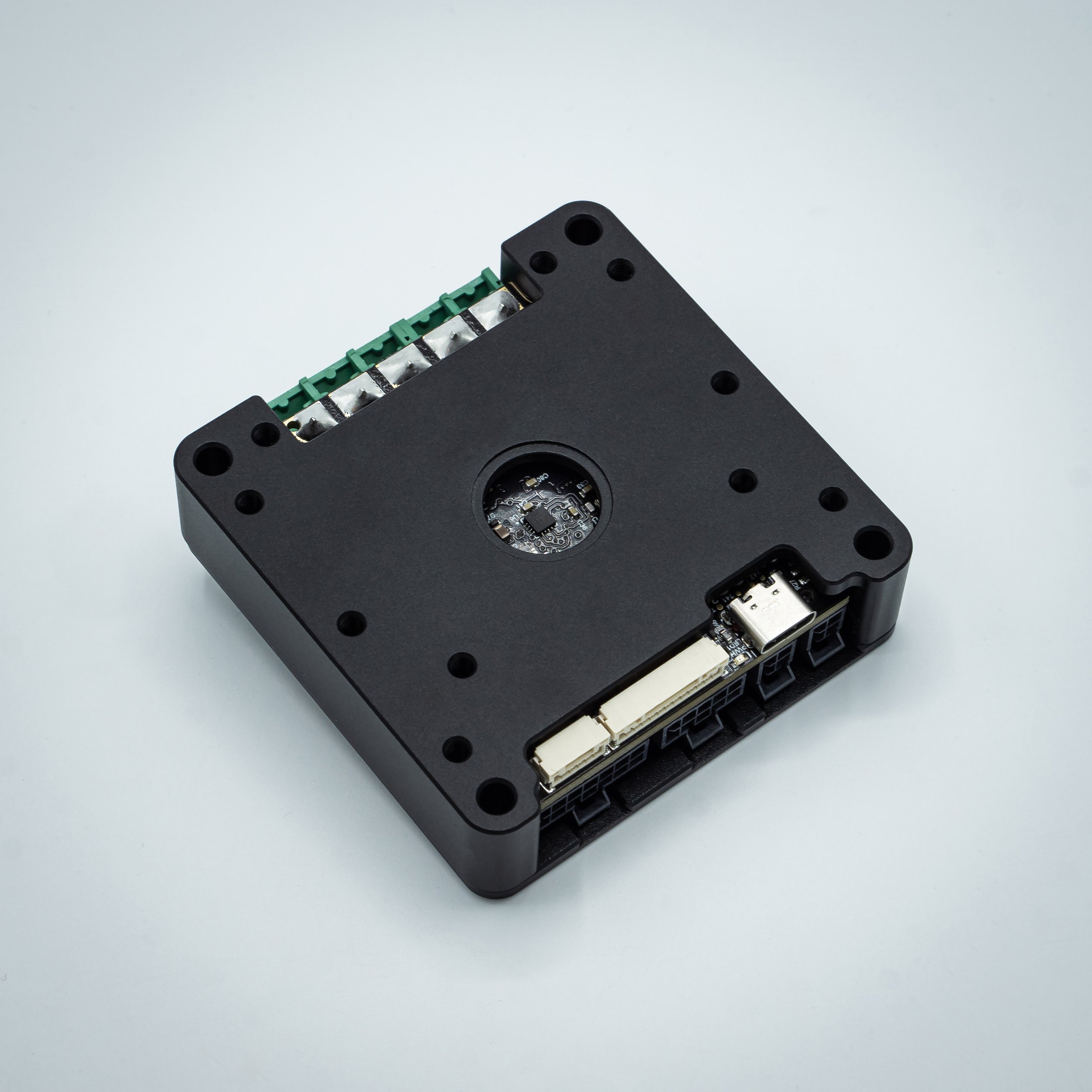

Shown with enclosure or heat spreader plate: recommended, sold separately.

USB and DC input may not be connected at the same time, unless you use a USB isolator.

The ODrive Pro does not have a brake resistor driver and should hence be used with a battery or a regen clamp module.

Documentation: docs.odriverobotics.com

New browser GUI: gui.odriverobotics.com

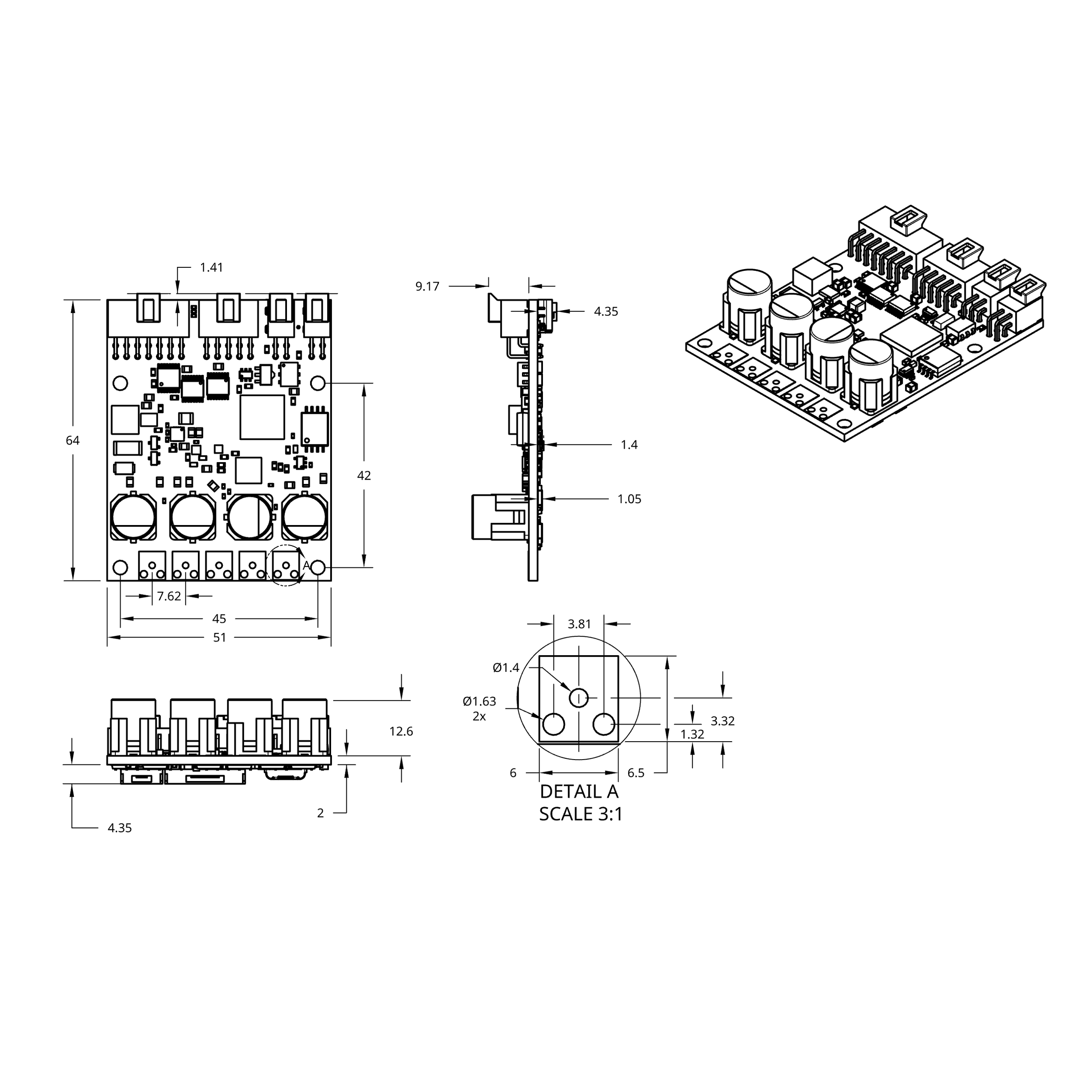

CAD files available to download here. Note there are multiple tabs.

Note that there is an upcoming change to the power pads as shown in the last image.

The firmware is not open source, but may be available under NDA to commercial partners.

The ODrive Pro meets the needs of your demanding robotics application, with:

Locking connectors for high reliability wire harness

Ultimate reliability and high performance in 5 x 6.5cm

Dual absolute encoder support for precise load positioning and instant cold starts

Up to 5kW peak, 3kW continuous power with appropriate cooling

Shared software architecture with all current generation ODrives, including Web GUI support

Features & Specs

Single-axis (controls 1 motor)

High performance servo control of BLDC, PMAC, and ACIM motors

Torque, velocity, position, and trajectory control modes

Sensorless speed control

12-56V Operation (58V max)

Up to 70A continuous, 100A peak current with heatsink and fan

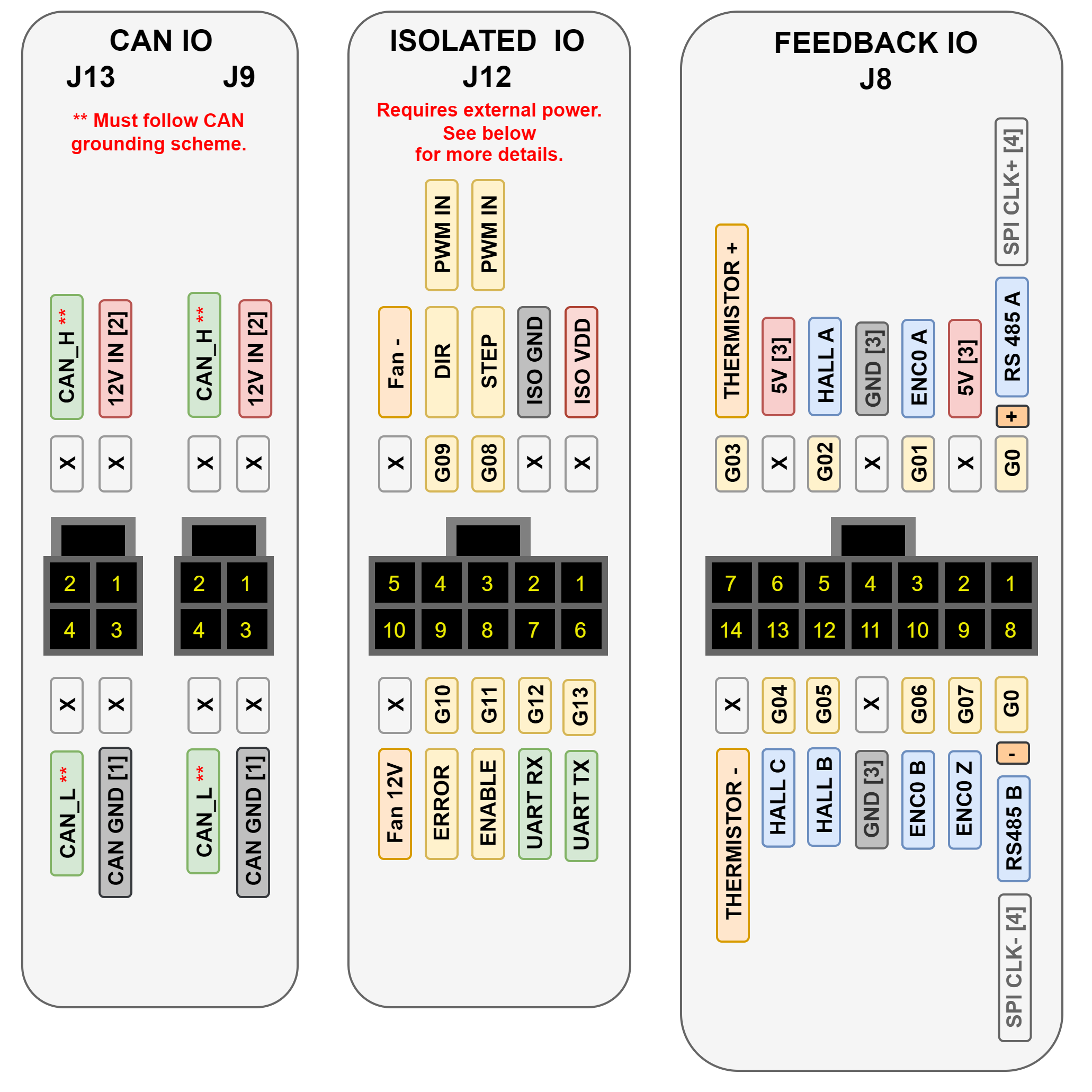

Control over USB, UART (Isolated), STEP/DIR (Isolated), Analog Voltage, PWM (Isolated), and CAN (Isolated)

Electrical Features

CAN 2.0B @ 1Mbps Control (10Mbit/s CAN-FD, experimental)

On-board magnetic encoder: MA702

Supports offboard quadrature, hall, SPI, SSI, and RS485 encoders. BiSS-C support coming soon.

Incremental encoders and hall sensors have on-board input filters

Isolated CAN, UART, Step/Dir and PWM control inputs

Locking IO connectors with a diverse and flexible feature set.

Mechanical Specifications

Mass - 35g (no screw terminal) | 55g (screw terminals present)

Board Perimeter - 51mm x 64mm

Locking Molex Nano-Fit connectors for IO & Feedback

Locking, low profile JST-GH connector for extra IO

Controls Specifications

24kHz PWM frequency - 48kHz motor ripple current frequency

8kHz control loop frequency (24kHz current control loop coming soon)

700Hz max recommended electrical frequency (2000Hz support coming soon)